Post by TasunkaWitko on Jul 12, 2012 16:43:28 GMT -5

First attempt at Buckboard Bacon

Back in Februrary, I made my first attempt at buckboard bacon, which is made from a pork shoulder, rather than the belly. Buckboard bacon, under various names and with many slight variations, is an old tradition in in the pork-eating world, going far back into history. It is a delicious and practical way to make use of a pig carcass, especially in times and places where meat, of any kind is a precious commodity. The curing process preserves the pork, so that it could be eaten long after the hogs were slaughtered. Buckboard bacon is very easy stuff to make, with a goodness all its own. There are dozens, probably hundreds of varieties you can create, using different flavours, and it is worth looking into, if you enjoy charcuterie.

In my case, I used a boned-out pork shoulder that I had trimmed (actually over-trimmed, I think) of its fat. Being my first attempt, it did not go as well as it could have, but the process and method are sound, and it is a good base from which to make further attempts.

Note - I didn't get too many pictures of the process, especially in the early stages, but it is similar to other curing procedures. I used Tender Quick as a curing agent and, following their instructions for whole cuts of meat, I employed 1 tablespoon of cure per pound of meat and cured at least 5 days per inch of thickness. I also used, as part of the cure, and equal amount of turbinado (raw) sugar (1 tablespoon per pound). During teh curing process, I kept the pork in a sealed ziplock bag in the refrigerator - with the air squeezed out - and rotated the bag once or twice a day to keep it covered with curing agents.

The boning and trimming resulted in four chunks of meat - no worries, it all ends up the same! Here are the chunks after curing and sitting uncovered in the refrigerator overnight in order to form a pellicle:

Here they are after smoking for a few hours over hickory, then finishing in a slow oven up to an internal temperature of 140 degrees:

I sliced one of the chunks open, and was rewarded with some good-looking stuff:

It was a little leaner than i expected, but no worries. It looked and smelled great. Here's another chunk, sliced open:

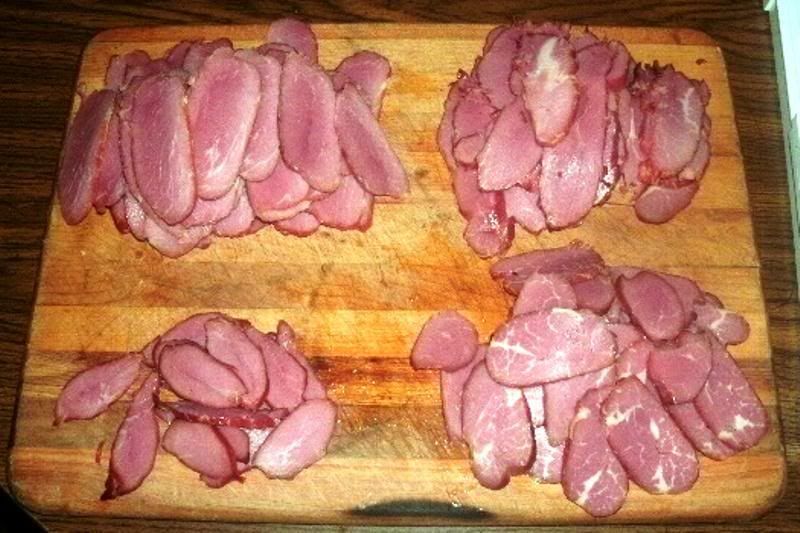

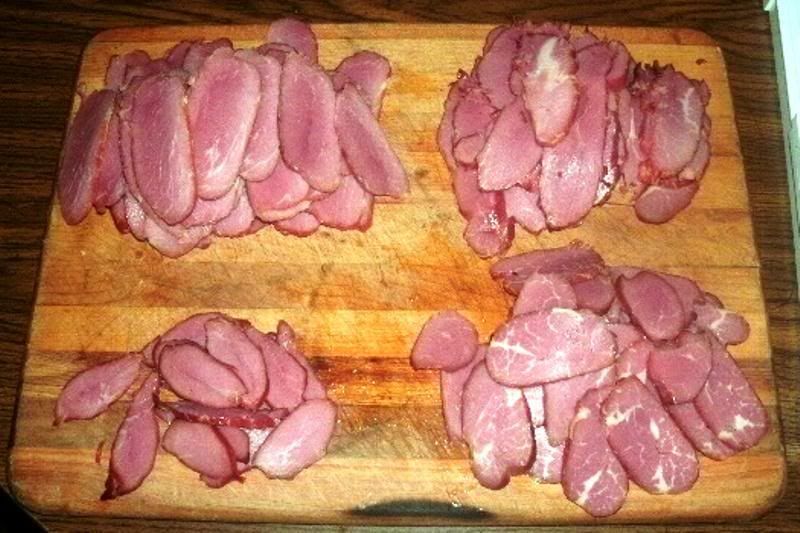

I ran all four chunks through my slices, at a thickness roughly the same as thick-sliced bacon:

Everything looked good, so I packaged it up and put it in the freezer:

I had a few scraps:

So I fried them up:

And tried them on a sandwich with tomato.

The bacon turned out very good! It has a nice, smoky aroma to it while cooking, and full sweet/salty/smoky flavour. As I noted above, it was a little leaner than I expected, but this isn't really anything to get worried about. Even as lean as it was, it was still better than most bacon I've bought in my time here on the planet.

Back in Februrary, I made my first attempt at buckboard bacon, which is made from a pork shoulder, rather than the belly. Buckboard bacon, under various names and with many slight variations, is an old tradition in in the pork-eating world, going far back into history. It is a delicious and practical way to make use of a pig carcass, especially in times and places where meat, of any kind is a precious commodity. The curing process preserves the pork, so that it could be eaten long after the hogs were slaughtered. Buckboard bacon is very easy stuff to make, with a goodness all its own. There are dozens, probably hundreds of varieties you can create, using different flavours, and it is worth looking into, if you enjoy charcuterie.

In my case, I used a boned-out pork shoulder that I had trimmed (actually over-trimmed, I think) of its fat. Being my first attempt, it did not go as well as it could have, but the process and method are sound, and it is a good base from which to make further attempts.

Note - I didn't get too many pictures of the process, especially in the early stages, but it is similar to other curing procedures. I used Tender Quick as a curing agent and, following their instructions for whole cuts of meat, I employed 1 tablespoon of cure per pound of meat and cured at least 5 days per inch of thickness. I also used, as part of the cure, and equal amount of turbinado (raw) sugar (1 tablespoon per pound). During teh curing process, I kept the pork in a sealed ziplock bag in the refrigerator - with the air squeezed out - and rotated the bag once or twice a day to keep it covered with curing agents.

The boning and trimming resulted in four chunks of meat - no worries, it all ends up the same! Here are the chunks after curing and sitting uncovered in the refrigerator overnight in order to form a pellicle:

Here they are after smoking for a few hours over hickory, then finishing in a slow oven up to an internal temperature of 140 degrees:

I sliced one of the chunks open, and was rewarded with some good-looking stuff:

It was a little leaner than i expected, but no worries. It looked and smelled great. Here's another chunk, sliced open:

I ran all four chunks through my slices, at a thickness roughly the same as thick-sliced bacon:

Everything looked good, so I packaged it up and put it in the freezer:

I had a few scraps:

So I fried them up:

And tried them on a sandwich with tomato.

The bacon turned out very good! It has a nice, smoky aroma to it while cooking, and full sweet/salty/smoky flavour. As I noted above, it was a little leaner than I expected, but this isn't really anything to get worried about. Even as lean as it was, it was still better than most bacon I've bought in my time here on the planet.